(IF YOU DON’T KNOW WHERE YOU ARE, THEN?…)

I’ve decided to shift gears and speak to something a bit different than previous blogs. It is centered around a simple yet very important lesson I enjoy teaching and reviewing with my Robotics club students. It’s also taught to all first-year engineering students but I don’t believe enough emphasis is placed upon this straightforward principle. Especially since it’s the basis of all machines, assemblies, and parts. Whereas without the proper implementation, most machines would not assemble or work properly.

As engineers, we know them as datums, described by a simple definition per the Oxford dictionary, “a starting point of a scale or operation”. An assignment of a name and definition does very little for us on how to apply and implement these effectively. Also, over the years I have surprisingly discovered that many engineers do not employ this very basic principle at the inception and throughout their engineering and designs.

As a machine engineer, I explain that all machines are about one simple principle, holding things in place or allowing them to move. This is often easier said than done as can be seen by the monumental achievements of mankind, doing just that. Regardless of whether it’s the Blue Origin blasting William Shatner (Captain Kirk) into space or the mundane box your mail is delivered to, it’s all about this principle.

I begin by explaining that in the realm that we and our machines exist, things need to be located and positioned. As an engineer, it’s all about controlling and defining those locations and positions (and a bit about the process from A to B, but that’s for another blog or two). For this, we use a coordinate system, because if we don’t know where something is, we can’t keep it there or move it somewhere else.

I begin by explaining that in the realm that we and our machines exist, things need to be located and positioned. As an engineer, it’s all about controlling and defining those locations and positions (and a bit about the process from A to B, but that’s for another blog or two). For this, we use a coordinate system, because if we don’t know where something is, we can’t keep it there or move it somewhere else.

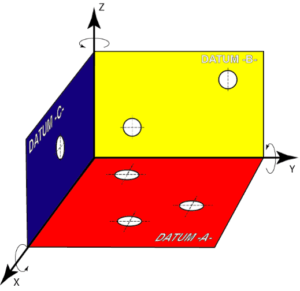

So, in mechanics, we deal primarily with 6 Degrees of Freedom (DOF), 3 freedoms of translation (X, Y & Z), and 3 freedoms of rotation (rX, rY & rZ). Simply put, let’s call forwards and backwards the “X-axis”, left or right the “Y-axis” and up and down the “Z-axis”, (positive being forward or coming towards us, to the right and up; negatives are the opposite). Now this for the non-engineers may have already gotten too complicated, the OMG of hearing positive and negative is suggesting math, yikes… So, as I like to explain to my students, it can be simplified to the fact that as machine designers, we need to hold things in place or allow them to move.

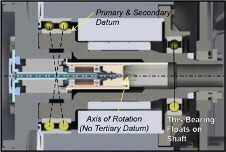

Let’s establish what we need to do, to do just that. This is a concept machinist and tooling designers know like the back of their hand and is the basis for how all things are engineered and manufactured. First, you require a primary flat surface, where three points establish that plane (aka flat surface). If we are on that plane, Datum A, this positions in one degree of translation (Z) and two degrees of rotation (rX & rY), OK! that’s 3 of 6 DOF taken care of. Secondly, we require two additional points in space, where we create a second plane through those two points and perpendicular to the first plane, our secondary datum (Datum B), this now constrained two more DOF, one translation (X) and one rotation (mZ), ok, that’s 5 of 6 DOF. Finally, we establish one more point in space that constrains that final translation degree of freedom (Y), 6 out of 6 DOF = zero motion and fully constrained.

This seems relatively straightforward, however, during my 29 years of engineering it surprises me how often these basic principles of engineering are not adhered to. Mostly, I have found in the countless designs I have been asked to review or solve a problem with, is that the initial design is over or under constrained.

This seems relatively straightforward, however, during my 29 years of engineering it surprises me how often these basic principles of engineering are not adhered to. Mostly, I have found in the countless designs I have been asked to review or solve a problem with, is that the initial design is over or under constrained.

Generally, it becomes quite obvious when something is under-constrained, it’s moving in a direction that is not intended. However, this issue doesn’t always manifest itself as movement, often it shows up in an instability. When we over-constrain the problem isn’t as evident and can lead to unintended consequences, such as overstressed or deflected parts, assembly issues, or impossible tolerance situations.

Under-constrainment is obvious in the real world especially when we are under the influences of gravity or other forces. However, when engineering in the computer’s virtual world we are forced to locate parts of our design in virtual space without gravity and the potential for movement isn’t as obvious. Any engineer that has worked with motion simulations is all too familiar with DOF constraints. So, as we engineer our machines, we must continually be cognizant of this Imperative concept.

Under-constrainment is obvious in the real world especially when we are under the influences of gravity or other forces. However, when engineering in the computer’s virtual world we are forced to locate parts of our design in virtual space without gravity and the potential for movement isn’t as obvious. Any engineer that has worked with motion simulations is all too familiar with DOF constraints. So, as we engineer our machines, we must continually be cognizant of this Imperative concept.

Over-constrainment leads to part failures, whether premature life expectancy, impossible or inconsistent assembly issues, or over-stressed parts. This reminds me of a project I managed many years ago, where the tail gearbox housing of a large helicopter had feet that were fracturing. The running joke was to just “beef up” the feet so that we move the problem to the airframe, which was a different department, therefore, alleviating our department of the issue. Obviously, this wasn’t pursued and would have been a bad decision. However, all too often engineers’ first intuition when parts fail is to strengthen or stiffen, when the real solution may be in reviewing the constraints and removing the constraints that are the culprit.